Artisanal labor can be defined as work done with personal flair, pride in quality of craft, and the business independence to sustain that style of production. In our research project in Detroit, we include hairstylists, clothing and jewelry makers, urban farmers, furniture makers, and many other occupations. These small worker-owned enterprises are not creating high incomes. But by social measures–high in race and gender diversity, attentive to environmental sustainability, and committed to “giving back” through community services–they are exactly how the economy should be composed. Is it possible that AI, robotics, and other forms of technology could empower their production and services, create business to business collaborations, and offer new forms of consumption that turn worker-owned enterprise into an entire economy, one that is based on generative justice?

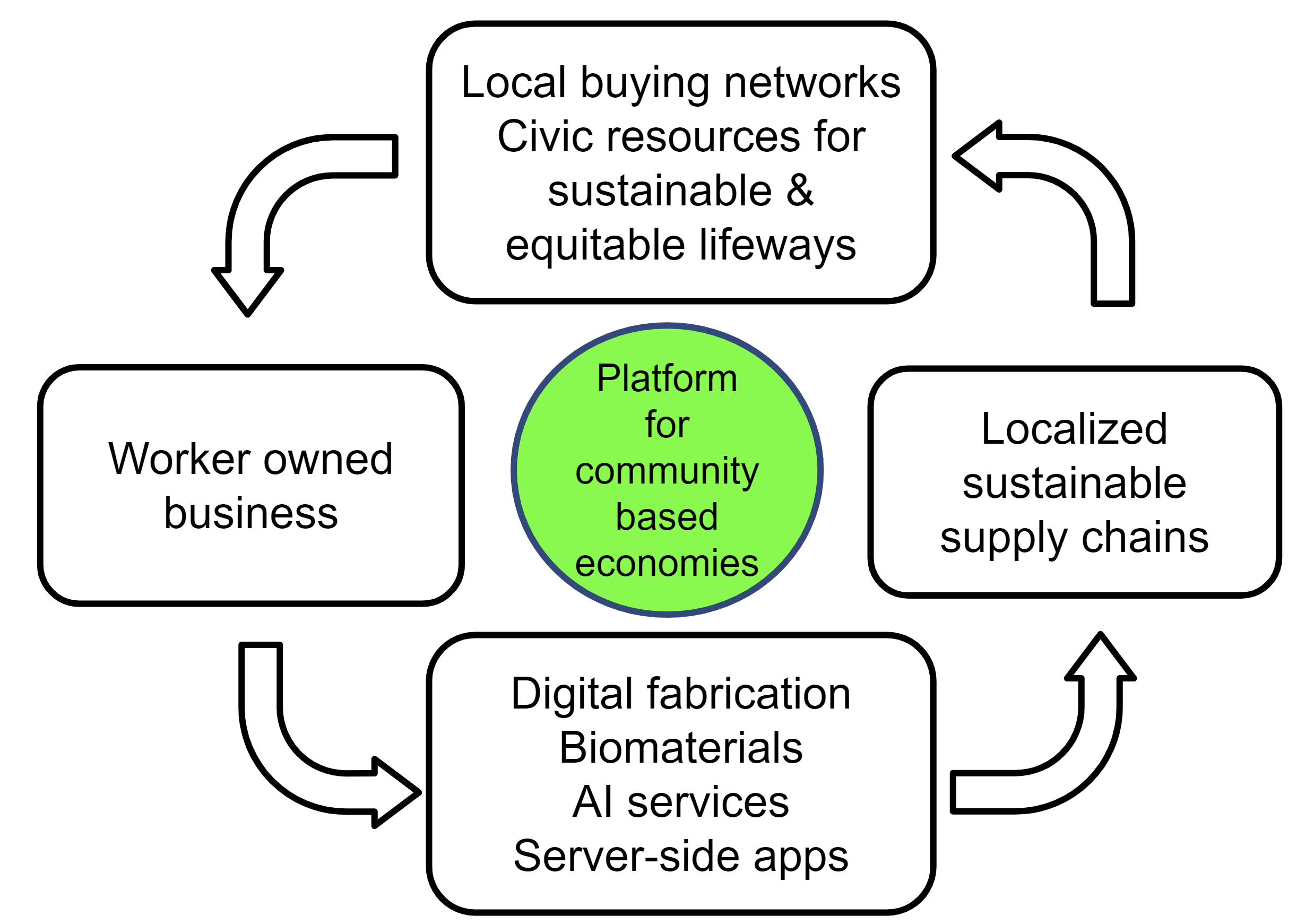

Above is a flowchart for how that might work. We refer to this as a “community-based economy”, because the idea of returning value to those who created it will require a collaboration of local ecosystems, civic organizations and worker-owned businesses. Some of this is described in our publication here (for the K-12 education version, see AI Keepin’ it Real). The NSF kindly provided our funding with a grant titled “Race, Gender and Class Equity in the Future of Work: Automation for the Artisanal Economy”.

Once we recruited our participants from Detroit worker-owned businesses, we started at the micro-scale. How can laser cutters, 3D printers, AI fashion design, digital soil sensors and other technologies empower production without sacrificing what artisans love about their work? At the meso-scale, we look at how cloud-based services can enable collaborations between enterprises. AI has a role here in linking local producers horizontally, substituting imports with more sustainable, local value chains. And at the macro scale, how can we create online markets that let consumers connect directly with producers, form buying groups with other customers, find more authentic sources for sustainability and other priorities? A community-based economy could also launch its own social media platforms to facilitate less toxic, polarizing communications, democratic process, and civic sphere collaborations, which in turn provide the local government support to sustain worker-ownership.

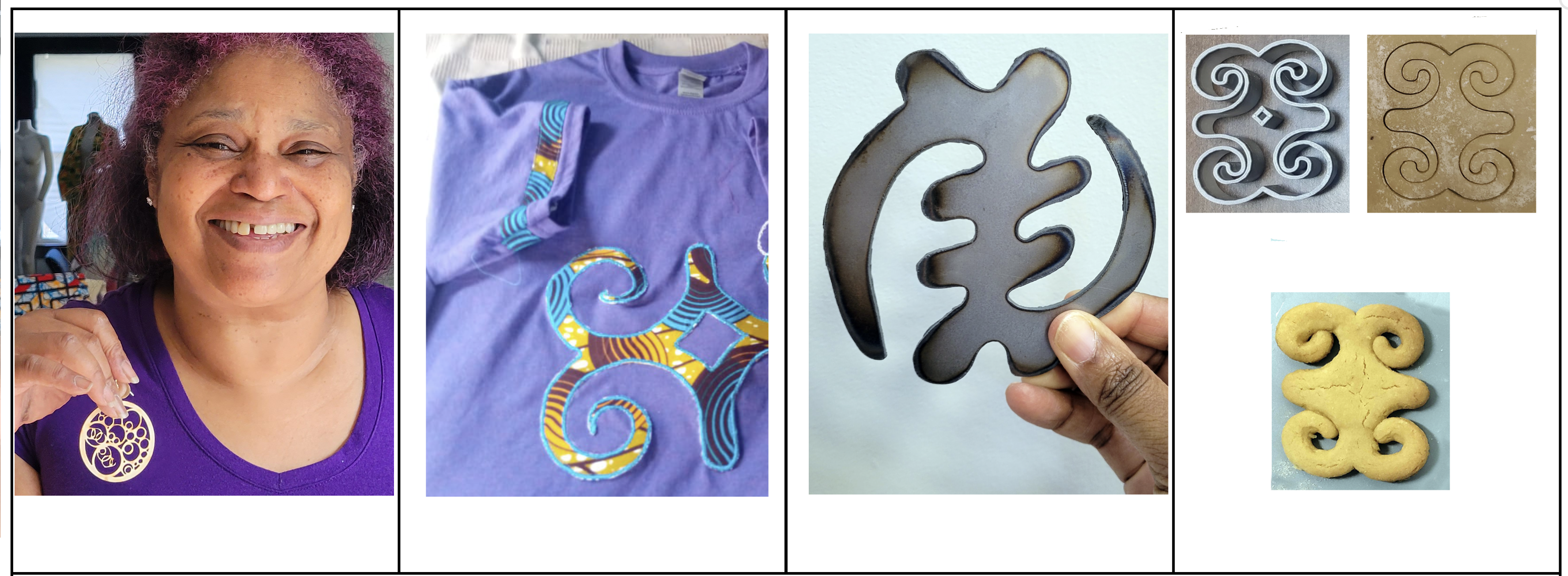

In some cases the technology protects the hand-made, such as our system for using AI to spot factory-made fakes. In other cases we help artisans “translate” between the physical and virtual domains. We call these “heritage algorithms”. Through interviews with artisans we learn about the math and computing ideas they are embedding in their crafts, and create an interface that makes those available as “heritage algorithms”. For example, cornrow braiding in the US shows elegant fractal scaling patterns that combine both contemporary innovation and Africa’s fractal heritage. These have been developed as coding lessons for underrepresented students as well as 3D printing products for urban salons:

Some of the experiments in digital fabrication include laser cut earings, fabrics and wind chimes; as well as 3D printing for items like cookie cutters, using cultural themes such as adinkra and fractals. Other technologies we examine include Direct to Garment Printing, digital embroidery and metal casting.  Because Detroit has so many urban farms, tech for growing was a natural next step. One of our participating farms, TheJoyProject, used the technology funds to install a combination of solar power and water pumps. We developed that into a local grant proposal, and were able to fund another 5 systems for solar power and rain harvesting.

Because Detroit has so many urban farms, tech for growing was a natural next step. One of our participating farms, TheJoyProject, used the technology funds to install a combination of solar power and water pumps. We developed that into a local grant proposal, and were able to fund another 5 systems for solar power and rain harvesting. That allowed small farms without electricity or running water to use digital tech control for pumps and sensors. Other farm tech we supported has included a lawn bot, a high-capacity herb dryer, and a temperature and humidity controlled egg hatchery.

That allowed small farms without electricity or running water to use digital tech control for pumps and sensors. Other farm tech we supported has included a lawn bot, a high-capacity herb dryer, and a temperature and humidity controlled egg hatchery.

The next challenge is to help local growers get connected to local makers (e.g. biomaterials for furniture, fabrics, etc.), so that a community-based ecosystem of production starts to form. For example, we developed the African Futurist Greenhouse to see if Detroit’s African bead museum could revitalize traditions such as seeds for beads and dyes from plants, or new innovations such as laser etching locally grown materials.

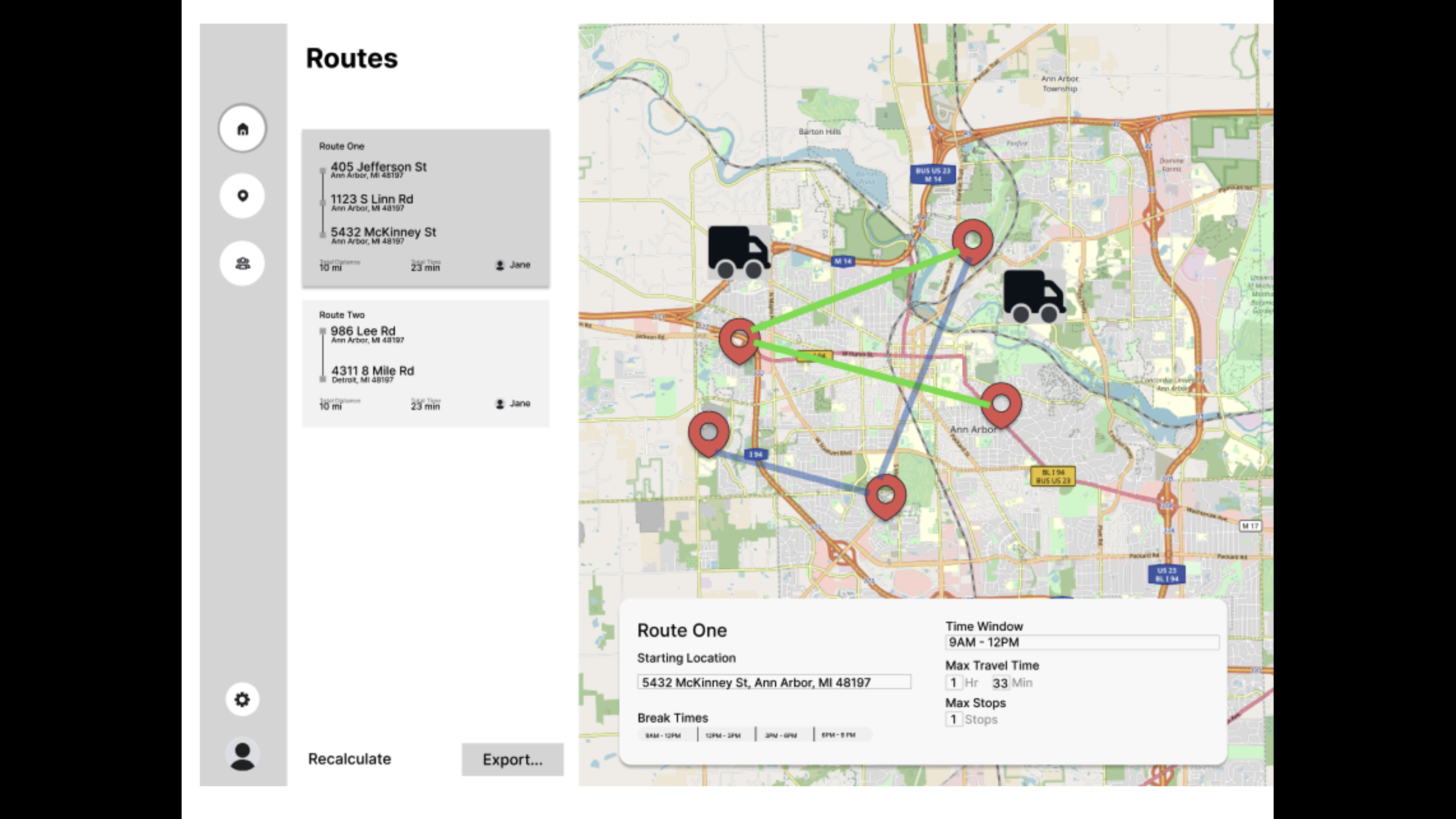

One of the most important areas has been developing a local system for e-delivery; a way to help local growers connect with consumers on a system they own and control, rather than seeing big companies take a cut of their profits:

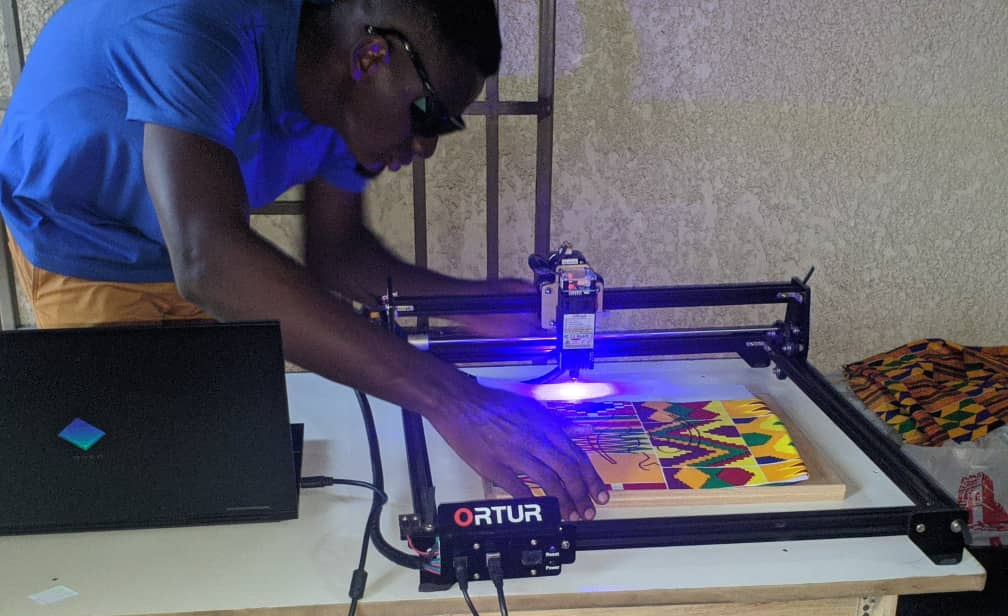

There is a role for thinking globally as well. Take for example Ghana’s tradition of logarithmic curves in adinkra symbols. The simulations and cultural meanings can be found here. Learning to program simulations can upscale artisans skills, rather than the deskilling that usually accompanies automation. And simply providing a laser cutter is sufficient to then apply those simulations to all sorts of efforts. With another grant we helped our partners in Ghana launch AfroFuture Fashions , using a combination of simulation and laser cutter to create matching adinkra shirts and masks for the pandemic.

Linking this group with our Detroit artisans, we hope to develop community-based e-fulfillment, in which textile designers here can experiment with AI-generated patterns. We asked the Ghanaian weavers to pick out the ones they prefer to make, and ship those back to Detroit to be incorporated into clothing by those textile designers.

There are also opportunities to create local links with community activists, educators, environmentalists and others. For example, we developed a new line of copper wire jewelry for Dabl’s MBAD African Bead Museum by raiding electronic waste bins and bringing in art students as interns.

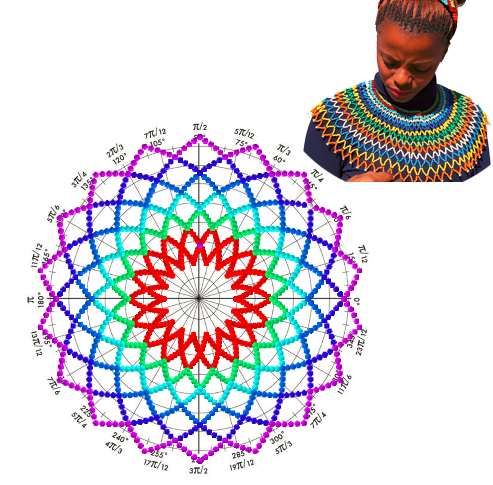

African designs often include patterns that can be understood as radial or polar. That is to say, they are easily modeled using combinations of changing radius and changing angle:

Batik fabricators in Ghana use latex foam to carve out these shapes. However the latex does not decompose; so the trash heaps grow. As one cyborg alternative, we created 3D printed molds, and grew fungus-based foam (thank you Ecovative!) inside it. Lay artisans can use our blocks based cultural computing to create the designs that go into the 3D printer, increasing their skill sets, and improving sustainability with biodegradable stamps:

Unfortunately the fungus foam is not as porous. They had to dip it into the wax more frequently, and even then the transfer was not as complete.

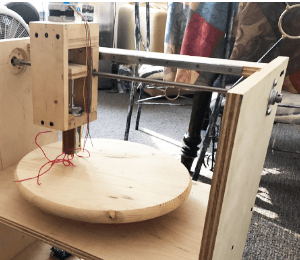

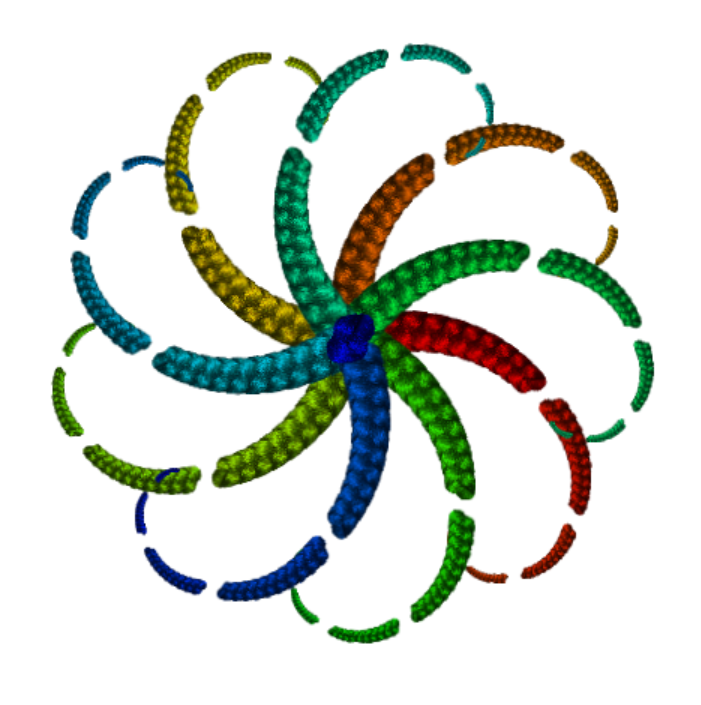

Our new approach has been the development of a batikbot. While 3D printers are designed as cartesian coordinate systems, we decided to first try the African polar coordinate tradition for the batikbot hardware. This may allow some new efficiencies. In many cases it takes less energy to use a polar mechanical system to create polar designs, and less wear and tear on the mechanism (converting between linear and circular motion has plagued mechanical engineering in everything from steam engines to walking robots). But if efficiency is allowed to become the over-riding goal, humans will lose out. This is really about extending the pleasures, meanings and social ecologies embedded in artisanal labor through hybrid forms that maintain grassroots ownership, empowerment, and collaboration with nature.

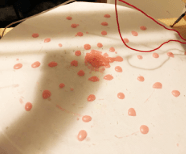

UM undergrad Yuki Fang started with a simulation that was simple enough for lay users to manipulate, but open enough that they can gradually recode and adapt it as a source of their own innovation: https://csdt.org/projects/10110/run. Meanwhile, RPI undergrad Allen Liu created a hardware prototype. The wax is a little “gloppy” but a great start!

Once the prototype is revised, we will take it to Ghana. But we can also extend this system to incorporate innovation for locally grown organic dyes: https://generativejustice.wordpress.com/solar-dye-in-ghana.

Another approach is to use laser cutting to create pressure templates. In the example below undergrads at Stamps school of Art and Design worked with Detroit artisans to create heritage algorithms from sources such as cornrow braiding patterns. Then we laser cut a template and push fabric into the holes to create a dye resist pattern.

They also developed a technique for laser-cutting recycled wood using heritage algorithms, and dying the forms with plant-based colorants (either indigo or turmeric). The designs will go on sale soon at the African bead museum in Detroit, where we hope to transfer to technique from the high powered university lasers to lower powered versions that can be installed on site.